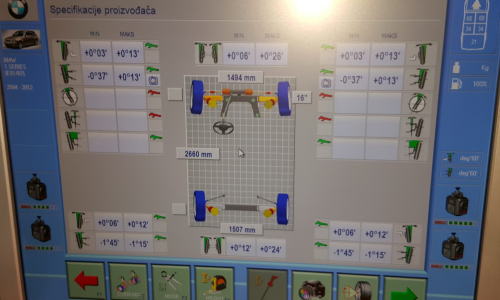

Car geometry centering

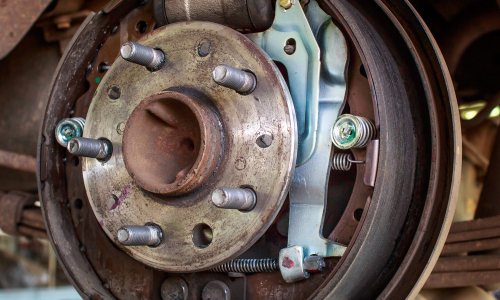

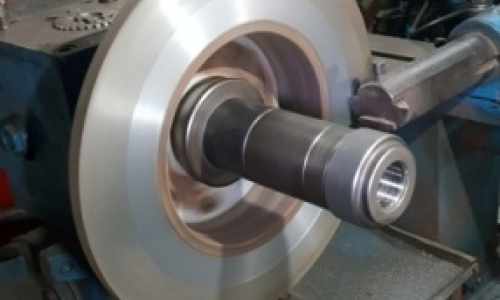

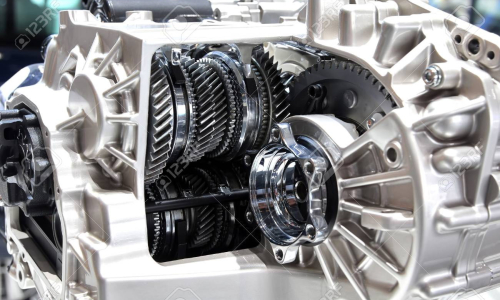

Vehicle geometry is a serious factor for safe and secure driving. It provides a safe and secure ride while saving tire consumption by wearing them properly. When working on the suspension system, replace any part: shock absorbers, fork forks, shoulders, ends of clamps, bearings, hub, steering rack or tire replacement, it is obligatory to center (adjust) the traps.

These parts are consumables and their failure affects the stability and safety of driving. Tire wear on the outside or inside. These are symptoms of malfunctions and wear of some of the mentioned parts. To check the correctness of the shock absorbers on the vehicle, we use a special machine for testing the shock absorbers. We check with the Eusama machine, which has scales for accurate checking of the shock absorbers and wheel clearances, as well as visual inspection.

After testing, we print the document so that the user of the vehicle has an insight into the condition of the vehicle and its right condition.

OVERVIEW OF VEHICLES WITH SPECIALISED DEVICES

VISUAL INSPECTION OF THE VEHICLE

We must first remove the fault by replacing the worn parts, and then perform the geometry of the vehicle to the factory measurements.

After replacing the parts, we are working on the geometry of the vehicle with the latest generation machine, produced by FASEP.

The machine works via cameras and uses radio waves instead of cables. It has the latest generations of vehicles in its database, which we update every year with factory data for the latest generation vehicles.

Centering (adjustment) of the vehicle geometry is performed on passenger and light trucks.